CAM Software Cuts Production Time, Increases Quality

Performance Motion's business growth necessitated increased efficiency and expanded capabilities. Implementing Vero's WorkNC CAM software reduced cycle times, improved quality and expanded capabilities.

Share

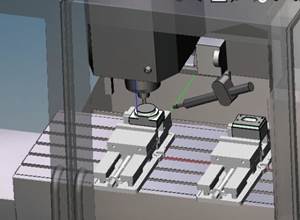

While Performance Motion historically has catered primarily to hobbyists—customers with a knack for designing and building expensive “toys,”—it is also expanding to incorporate other markets and take advantage of its growing capacity by performing general machine work. As business has picked up, the company’s three partners have seen plenty of opportunity for future growth if it increases its efficiency and expands its capabilities. To accomplish this, they decided to acquire a new five-axis machine tool. However, the partners knew they would also need to invest in new CAM software to ensure full use of the machine’s capabilities. Using Vero software to program its new Hurco machine, the shop was able to do just that, along with reduce cycle times and improve part quality. It was also able to extend the CAM benefits to its older three-axis machinery.

Based in Xenia, Ohio, Performance Motion specializes in making motion-controlled products for CNC equipment—specifically touch probes, rotary tables and 3D printers—and the software needed to program this equipment. The company makes hundreds of parts to produce a probe, while 3D printers and CNC rotary tables require 40 to 50 parts. Performance Motion designs, develops and manufactures 90 percent of its products in-house, including hardware, software, electronics and circuitry, catering primarily to hobbyists. However, it has been expanding to incorporate other markets and taking advantage of its growing capacity by performing general machine work. Yet, one challenge in this expansion was its three-axis machinery.

“We were at the point where we were designing parts that could be made on the equipment we had rather than parts that we really wanted to make,” says plant manager and co-owner Vic Hartings. “It worked, but it wasn’t the best.”

To remedy this, the company acquired a new five-axis Hurco mill and decided to try the WorkNC CAM solution by Vero Software (Southfield, Michigan). After two days of training on the new Hurco and a one- or two-hour crash course in WorkNC, the shop was up and running, making five-axis parts in a couple of days.

In particular, Mr. Hartings saw improvements in a rotary-table housing application. What once took 45 minutes to produce using his former software and a three-axis machine with indexer now takes just 17 minutes using the new Hurco and WorkNC. Plus, the new process achieves twice the quality, and cycle times are a third to half of that they used to be in some cases, he says. Moreover, making customer-specific changes on the fly takes just a few minutes.

Mr. Hartings credits WorkNC’s Dynamic Stock Model Management for this increased productivity. Machining the rotary table requires removing a great deal of stock before finishing operations can be performed, and WorkNC enables Mr. Hartings to constantly update the stock model of the part as he programs.

For example, he can program a 2-inch aluminum cutter to remove the main bulk of material, then change to a 0.5-inch end mill and, finally, to a 0.250-inch end mill to complete the finishing. As the tools decrease in size, WorkNC can identify where the 2-inch cutter was too big to access leftover material, and it uses the 0.5-inch cutter in those spots, leaving just enough material for finishing, he says.

In addition to reducing cycle time, the shop was able to improve the quality of the rotary-table housing with WorkNC’s Auto Engrave feature. Auto Engrave simplifies the creation of text and numbers as WorkNC curves that can be directly positioned inside a chosen view. Complete curve sets, or engravings, then can be saved as templates for reuse.

The benefits of the CAM implementation have also extended to the company’s three-axis machinery. By reprogramming older, three-axis parts in WorkNC, the company has been able to save time and improve part quality, especially with flat-surfaced parts that feature different sizes of holes and pockets. WorkNC’s Flat Surface Finishing tool path is optimized for high-speed machining, and designed to deliver smooth spiral pocketing and a large angle radius. This feature helps Performance Motion create one fluid tool path to complete all the finishing work on the flat surfaces.

With the former CAM package, the shop had to machine flats and walls in two separate operations. This created two problems: Mr. Hartings had to spend more time programming the part in the CAM software, and it created extra tool paths that weren’t needed. For instance, the cutter would make an extra pass in the corner, or edge, of a pocket that was already machined in the previous operation. WorkNC fixed the two problems by programming one tool path for finishing both the floors and walls of a part, he says.

Another feature, the WorkNC Drilling Manager, also helps save programming time by automatically detecting holes in the part model and displaying the information in a window that enables Mr. Hartings to easily and quickly assign center-drilling, drilling, tapping, boring and thread-milling operations. This is a significant time-saver when there are a bunch of holes in a part, he says, especially in five-axis machining.

For Mr. Hartings, who enjoys both new machining challenges and the predictable “normalcy of production,” another benefit of using WorkNC is the ability to devote time to tackling new projects with greater freedom.

“What’s really cool about WorkNC is the automation,” he says. “I can load my part, set up my stock and easily go from there. The software knows a lot, in the background of the program, about how to machine a part. It allows the programmer to think about the more complicated work by automatically taking care of the easier stuff. WorkNC takes something relatively easy, but time-consuming, and makes it quicker and easier yet.”

In addition to the automation inherent to the software’s Drilling Manager, WorkNC’s automatic collision-checking capabilities have increased efficiency at Performance Motion. For example, in finishing operations, the collision check will machine everything it can without colliding the tool and toolholder with the part, then it only saves the toolpaths that are collision-free, Mr. Hartings says.

The collision-checking capabilities of WorkNC paired with the new five-axis machine have also enabled the shop to tackle previously untried projects such as designing a new engine block for radio-controlled cars. The three-axis machines could not have taken finishing passes that have only 0.05 inch of clearance between the spinning toolholder and the finished part’s surface with the previous software, he says.

WorkNC also enables the shop to machine more complex parts. According to Mr. Hartings, what would have taken five to six hours to program using the old software now takes about an hour. That extra time can now be spent on tasks other than programming.

An added benefit of the automation and overall increased efficiency of WorkNC is that Performance Motion can now focus on the design and production of prototype parts. Mr. Hartings utilizes CAD software, as well as the CAD capabilities of WorkNC, to produce solid models that are easily imported into the CAM software. He says he usually has a part running on the machine or done in his hand within two to three hours of loading the part in WorkNC.

“WorkNC allows us to design something, make it and prove it out in a short period of time,” he says. “What’s interesting for us is that we make 3D printers, and we print a lot of prototype stuff on our printers. In some cases, I can machine the part in less time than it takes me to print it.”

While Performance Motion has never produced molds from which it could produce its own parts, the addition of WorkNC stands to change the game for Mr. Hartings and his team. In fact, the company is gearing up to release its first molded part.

“With WorkNC, we have the capability to make our own molds and parts,” he says. “It’s a huge cost savings. It’s really opened up a whole other capability for us.”

Related Content

Building A Powerful Bridge from the CAM Programmer to the Shop Floor Operator

SolidCAM for Operators provides a powerful bridge from CAM programming to the shop floor to best streamline the machine shop process with its CAM part simulation. It provides a clear picture to the operator for setup and prove-out, enables minor G-Code changes and avoids crashes, broken tools and scrapped parts.

Read MoreTTI Brings Specialty Gear Production In-House with Multiaxis Machining

By investing in a 3+2-axis machine and utilizing simulation software for diagnostic checks, Techtronic Industries turned a four- to ten-week lead time into a one- to two-week lead time.

Read MoreHow Integrated CAD/CAM Transforms Inventions Into Products

The close connection between CAD and CAM is what links creative ideas to practical production for this unique custom manufacturer.

Read MoreTurning the Corner on Virtual Machining and Simulation

Simulation software’s effectiveness comes down to proper implementation and alignment with shop priorities.

Read MoreRead Next

AMRs Are Moving Into Manufacturing: 4 Considerations for Implementation

AMRs can provide a flexible, easy-to-use automation platform so long as manufacturers choose a suitable task and prepare their facilities.

Read MoreMachine Shop MBA

Making Chips and 91±¬ÁĎÍř are teaming up for a new podcast series called Machine Shop MBA—designed to help manufacturers measure their success against the industry’s best. Through the lens of the 91±¬ÁĎÍř benchmarking program, the series explores the KPIs that set high-performing shops apart, from machine utilization and first-pass yield to employee engagement and revenue per employee.

Read More