-

SPONSORED

-

SPONSORED

Measurement Tools for Machining

Measurement tools are used to verify that a part’s dimensions conform to required tolerances. They include calipers, micrometers, gages, CMMs and profilometers.

ESSENTIAL READING

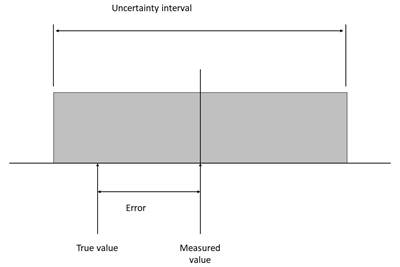

VIEW ALLHow to Evaluate Measurement Uncertainty

Manufacturing and measurement are closely coupled. An important consideration for the use of measurement results is the associated measurement uncertainty. This article describes common metrology terms and provides an example uncertainty analysis.

Read More6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

Read MoreHow to Choose the Correct Fixed-Body Plug Gaging Solution

The two types of fixed-body plug gages are both accurate, fast and easy to use. Consider these factors when selecting one for your gaging application.

Read MoreRethink Quality Control to Increase Productivity, Decrease Scrap

Verifying parts is essential to documenting quality, and there are a few best practices that can make the quality control process more efficient.

Read MoreHow to Calibrate Gages and Certify Calibration Programs

Tips for establishing and maintaining a regular gage calibration program.

Read MoreHow to Choose the Correct Measuring Tool for Any Application

There are many options to choose from when deciding on a dimensional measurement tool. Consider these application-based factors when selecting a measurement solution.

Read MoreLatest Measurement News And Updates

Common Methods for Measuring Workpiece Radii

With today’s complicated and very high-precision parts, workpiece radii can have a variety of shapes and contours. Sophisticated tools can help simplify the measurement process.

Read MoreHexagon CMM Streamlines Measurement Operations

The Maestro CMM features a digital-first architecture that provides rapid measurement routines, an intuitive user experience and seamless data integration.

Read MoreL.S. Starrett's Benchtop Measurement Platform Provides Repeatable Inspections

Eastec 2025: The L.S. Starrett Co.’s AVR400 gives users the option to measure a broad range of part sizes or larger runs of multiple parts.

Read MoreHow To (Better) Make a Micrometer

How does an inspection equipment manufacturer organize its factory floor? Join us as we explore the continuous improvement strategies and culture shifts The L.S. Starrett Company is implementing across the over 500,000 square feet of its Athol, Massachusetts, headquarters.

Read MoreTips for Ensuring the Performance of a Surface Finish Measuring System

Industry standards for surface finish help define the specifications of the instruments, how they are used, the results they provide and how they can be tested for performance.

Read MoreFeatured Posts

Marathon Precision’s Engineering Playground: One Shop’s Secret to Sustaining High Tech, Low-Volume and High Morale

Half an airplane on the wall, a ten-foot metal dragon, and a full-blown recording studio might not scream “manufacturing efficiency,” yet Marathon Precision proves otherwise. Here’s how forging, complex CNC operations and staff-driven creative projects combine to fuel the shop’s productivity and profitability.

WatchZeiss Showcases Innovative Metrology Technology at Online Event

Zeiss will reveal seven new metrology technologies and software updates at its Zeiss Live Tech Reveal on Thursday, February 27, 2025, at 2:00 p.m. ET.

Read MoreSimplicity Meets Function in Starrett Programmable Indicator

Programmable, touchscreen-controlled indicators like Starrett’s W4900 can perform a wider range of tasks than either dial or traditional digital counterparts while proving simpler to use.

Read MoreAutomating Fixed-Body Plug Gaging

How tight-tolerance gaging and in-process automation can converge to streamline manufacturing processes.

Read MoreAutomating Double-Flank Gear Testing

The form and surface finish of individual gears are becoming more demanding. Automated double-flank rolling tests are a particularly realistic measurement that simulates the behavior of the gears in operation.

Read MoreMeasuring Torque, Thrust Force for Smart Drilling Operations

To monitor drilling operations for smart manufacturing solutions, torque and thrust force can be measured.

Read MoreFAQ: Measurement

What is a caliper?

Calipers, which can be Vernier, dial or digital, are versatile tools for basic length measurement. They can be used on the shop floor, in the inspection room or even in the home by hobbyists.

Source: Caliper Tips And Tricks

What is a micrometer?

A micrometer consists of two opposing surfaces, a stationary anvil and a moveable spindle. On most micrometers, these hardened steel or carbide-tipped contact surfaces are flat. However, micrometers can also be equipped with contact tips with unique forms for measuring special part characteristics.

Convenience is one of the reasons the micrometer is often the tool of choice for length/diameter measurements. The basic micrometer provides direct size information quickly, has high resolution and is easily adaptable to many different measurement applications.

What is a gauge?

Gages are indirect reading instruments. The measurement units live not on the scale but off-site (for example, in a calibration room), and a master or other standard object acts as their substitute. The workpiece is compared against the master and only indirectly against the measurement units. The gage thus evaluates not the dimension itself, but the difference between the mastered dimension and the workpiece dimension. Examples of these comparative gages include an adjustable bore gage, mechanical snap gages or bench stands with dial indicators.

Gages tend to be faster and more accurate than measuring instruments. This is because they are dedicated to a particular size, and over their short range, they produce higher resolution and hence, greater accuracy.

What does CMM mean?

A coordinate measuring machine (CMM) is a measurement tool that consists of a motion system, a probing system, a computer and measurement software.

Source: Machining 101: What Are Coordinate Measuring Machines?

Measurement Supplier Categories

- Flatness Measuring Equipment

- Gages, Mechanical

- Gages, Electronic/Digital

- Gages, Electronic/Digital

- Laser Measurement Systems

- Calibration Equipment

- Comparators, Optical & Other

- Surface Finishing, Measurement Equipment Used For

- Data Collection Devices for Gaging, SPC, etc

- Coordinate Measuring Machines

- Coordinate Measuring Machines

- Coordinate Measuring Machines

- Roundness Measuring Equipment