New Possibilities from Process Consolidation, Customization, AI and More at MT Technology Series East 2025

When do broadening capabilities outweigh specialization (and vice versa)? In our recap of MT Technology Series East 2025, find out how the latest generation of machines, tooling and software answers that question.

Share

Which is more valuable in manufacturing: broad capabilities, or deep specialization? It’s a thorny question with a simple answer. Why not both?

(formerly known as EASTEC) saw many companies showcasing machines, tooling, software and more that can meet the needs of broad audiences as well as very specific needs. While it’s impossible to spotlight everything on display at the show, what follows are some examples related to process consolidation, custom offerings and AI.

Grob’s latest generation of its G550T mill-turn can perform gear skiving and fir tree-milling in addition to more expected mill-turn functions like standard milling and turning. Fir tree milling to produce parts like the one pictured has exacting machine requirements, with the large contact area on hard material requiring a very stable, rigid machine while both part and spindle spin.

Process Consolidation

Process consolidation showings at the show came in the form of multi-process machines as well as more unexpected forms, with highly versatile software, capability-increasing refinements to existing technology and technology to facilitate automated multi-process work.

Grob’s G550T mill-turn acted as the company’s centerpiece at the show. While the G550T mill-turn has been a part of Grob’s lineup since 2010, it has been updated over the course of several generations. In addition to traditional milling and turning, the G550T can also perform gear skiving and fir tree milling. The table can also rotate to machine the part upside down, improving reach and chip clearance to enable users to perform more operations and part programs on a single machine.

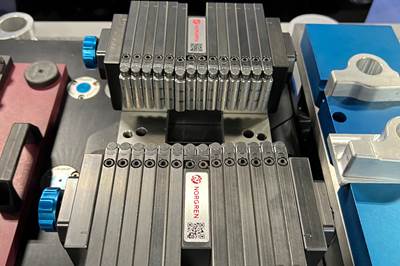

From a different perspective, Erowa has seen interest in its products grow because of their compatibility with mill-turn and multi-process machines, including B-axis lathes. The company offers workholding, automation, and support software that simplify complex manufacturing processes. In automation, Erowa has particularly targeted parts with long cycle times. It also extends automation not just to parts, but to pallets, enabling overnight automation, even with multiple jobs. Company spokespeople say this strategy is compatible not just with milling, but also with EDM work.

Rather than target its fixturing and automation tooling for individual parts, Erowa focuses on whole-pallet automation, which more easily enables automating multiple jobs to run lights-out.

Speaking of EDM work, advancements in EDM technology have led GF Machine’s staff at the show to suggest that EDMs could be used to perform work that once would have required a mill. The software onboard the company’s Cut F 600 automatically senses where to slow down and speed up based on part thickness, a function which protects against wire breaks, and technology that enables the wire to spark only at the bottom (rather than the bottom and the sides) improves precision. While company spokespeople say EDM work has long been a tool and die specialty, these advancements make it more viable as a substitute for end mills when creating certain parts. The EDM process generates less heat and deflection than traditional milling, GF’s staff say, enabling it to hold tight tolerances with relative ease.

TopSolid, meanwhile, has built on its original CAD/CAM software to consolidate many shop management processes into a single ecosystem. The company’s software can work as its original CAD/CAM software, as well as ERP software, robotic programming software and machine monitoring software. This common system can take in the data from these separate functions and use it to inform future work — for example, it can tell which machines are using which tools in real time, and if jobs being programmed require that tool, the software can warn users about capacity issues or tool wear issues.

By combining three drills for different operations into one, ARCH Cutting Tools has consolidated one customer’s tooling while eliminating the need to manipulate standard tools to perform some of these operations. Custom tooling is a key part of ARCH’s business, making up 75% of its tooling.

Custom Work

Multiple companies at the show emphasized custom solutions, both in tooling and beyond. ARCH Cutting Tools has found its niche in creating custom tooling for specific purposes and customers. One tool the company showcased at the event combined three drills into one, enabling the client to complete multiple drilling operations with a single tool, without the need to manipulate a standard tool in ways that required experience machinists. Fives’ CITCO tooling division performs custom edge prep to modify its tooling from ISO standards, and does a steady business designing and manufacturing custom PCD, CBN and diamond cutting tools for customers. Ceratizit has a full team working with customers on custom, 3D-printed tooling, with the lessons learned there also improving its growing catalog of standard 3D-printed tooling. Beyond its growing line of standard ceramic tooling, Greenleaf has also seen growth in the market for custom tooling designed for specific customer projects.

Tooling management software company Omega TMM says its claim to fame is its customizability. Shop floor and tool cabinet layouts within the software are user-customizable, and the software can integrate with CRM and CAM software, feeding data back and forth. Eastern US and Canada Sales Manager Nicholas Wiktorski says this helps users track their tooling stock and ensure they have enough of the correct tooling to perform their scheduled jobs.

Blue Photon’s chemical workholding works well with complex shapes, such as those produced through additive manufacturing. It also does not require a dovetail, helping simplify five-axis processes.

Blue Photon, meanwhile, has been able to expand its workholding business by working with partners to produce custom fixtures. In these situations, the partner companies produce the bottom half of the vise, while Blue Photon produces the chemical workholding grippers on the upper side. These grippers, which use an adhesive that activates with the application of UV light, can hold parts securely in a free state and eliminate the need for dovetail removal. Company spokespeople say this makes Blue Photon a good candidate for holding additive and five-axis parts. The company has also improved its familiarity with additive manufacturing to make more efficient support structures for the grippers while enabling the company’s equipment to conform to complex geometries.

MachineMetrics is also continuing its push into broader capabilities and MES territory through a custom applications builder and configurable dashboards, both powered by shop-side AI. Chief Commercial Officer Graham Immerman says that this functionality will enable shops to build custom programs quickly, even if they have no experience coding. The company has also been working to fully integrate with more ERP systems out of the box, providing an additional data source for the MachineMetrics software and expanding its functionality.

Among updates to MT-Linki and its robots, FANUC displayed a Levil Technology desktop mill equipped with one of its controls. While desktop milling is most popular in education applications, Debra Schug says that it has seen some use in space-starved companies. Industrial Partnership Account Manager Jeff Orleman at Rego-Fix also noticed the relative growth in the desktop milling market and says that his company has started making desktop mill toolholders as a result.

The AI of It All

AI has also been at the heart of advancements championed by other software companies at MT Technology Series East. ECI showcased its JobBoss2 and M1 manufacturing ERP software program, JobBoss for job shops with custom work and M1 for shops with more regular work and higher warehouse demands. JobBoss, with its functionality for the quick creation of parts and job entries, particularly benefits from ECI’s adoption of AI BOM Builder. This feature takes imported CSV and PDF files and extrapolates a bill of materials from features listed in the file. Engineers from the company say that this reduces the time to create these bills from minutes to seconds, with the time savings only improving as revisions require new bills of materials.

Many companies at MT Technology Series East promoted their ties to and success in the aerospace industry, mentioning that it appeared to be growing once again. Several companies also focused their offerings at the show on this audience, including Sumitomo, which showcased its binderless CBN tooling alongside a special grade of carbide tooling meant for titanium alloys.

Harmoni now features automated reports, with its own AI tool (facetiously called HAL, or “Harmoni AI Lieutenant”) undergoing testing and optimization. President David Caputo says that HAL will not only report on data and trends, but provide potential rationales behind the data, with it acting as a “shop floor manager, but Harmoni.”

Related Content

Data Visibility Boosts Beryllium Shop’s Revenue

Consistency is key for beryllium manufacturing, so the data visibility granted by Harmoni has swiftly become a vital, profitable tool in the shop’s arsenal.

Read MoreRefining Shopfloor Processes for Mission-Critical Parts

Pacon Mfg, Inc. has not rested on its laurels as the 2020 Top Shop Honoree for Shopfloor Practices and Performance. In the years since, it has refined its processes to continue excelling in a volatile market.

Read MoreERP and Process Changes Increase Shop’s Revenue 64% YoY

Implementing ProShop has led to a massive process overhaul at Marzilli Machine. From 2020 to 2021, revenue increased 64% without capital investment.

Read MoreMachine Monitoring Integrates With ERP to Reduce Errors

By investing in machine monitoring that links machine data with the shop’s ERP system, this machine shop broke down communication barriers and dramatically reduced errors.

Read MoreRead Next

4 Ways Eastec Evidenced Manufacturing’s Evolution

From tooling and workholding to Industry 4.0, the pursuit of new CNC machining opportunity united all who turned out for the 2021 event.

Read MoreThe 2025 Precision Machining Technology Show provided an excellent look at the variety of machining solutions catering to the U.S. metalworking industry, including a range of automation solutions for turned and milled parts.

Automation and Process Simplification Define Eastec 2023

Manufacturing technology at this year’s Eastec met the market with tools to streamline operations and assist machinists in achieving greater productivity.

Read More