Centerline Issues for Turning Inserts

Tooling experts Mike Fagan and David Grant suspect that many programmers and machinists could use a refresher on the importance and effects of insert alignment in turning operations. This short, amply-illustrated paper is their effort to clear up some of the misunderstanding.

Share

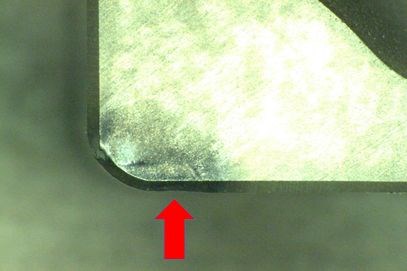

Photos of sample inserts such as this one illustrate wear patterns that help diagnose cutting tool misalignments in turning.

Tooling expert Mike Fagan suspects that many programmers and machinists could use a refresher on the importance and effects of insert alignment in turning operations. This short, amply-illustrated paper is his effort to clear up some of the misunderstanding.

It covers signs of misalignment and suggests ways to fix problems, with additional tips and advice to improve turning operations. To find the paper, click here.

Related Content

-

How to Troubleshoot Issues With Tool Life

Diagnosing when a tool is failing is important because it sets an expectation and a benchmark for improvements. Finding out why gives us a clue for how to fix it.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Measuring Torque, Thrust Force for Smart Drilling Operations

To monitor drilling operations for smart manufacturing solutions, torque and thrust force can be measured.