Micropulse Technology Comes To Fast-Hole EDM

Holes in turbine blades are critical because the internal cooling airflow provided by these holes prevents the parts from overheating during operation. One of the most promising technologies for making these holes is fast-hole electrical discharge machining (EDM).

Share

Forcing air through holes in metal parts is one way to keep them cool when exposed to high temperatures. Turbine blades in power generating equipment and jet engines are prime examples of components that depend on airflow to function in extremely hot environments. Machining these holes accurately and efficiently is a major challenge for manufacturers.

Electrical discharge machining (EDM) has been a mainstay in these applications because the process is capable of making small, deep holes in hard materials at high speed. A new development in fast-hole EDM technology seems to

offer a significant advantage in both drilling these holes and giving their openings a contoured shape.

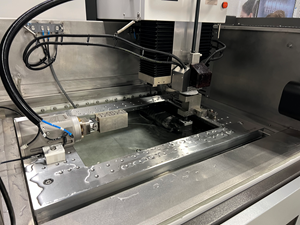

Beaumont Machine, a Milford, Ohio builder specializing in fast-hole EDM equipment, has come up with a way to control the rapid discharges of electrical energy that give EDM its name. Called micropulsing, the new method involves manipulating the frequency, duration and other characteristics of the electrical discharges.

Ed Beaumont, company president, says this technology enables users to avoid certain negative aspects of the heating and cooling cycles inherent in EDM. Although this development has a negligible effect on how fast EDM can remove material to "drill" and shape a hole, it virtually eliminates microcracking on a workpiece’s surface, Mr. Beaumont says.

According to Mr. Beaumont, micropulsing is especially effective on single-crystal alloys favored for critical aerospace and power generation components. In addition to almost no microcracking on these materials, micropulsing leaves a very low recast layer—the heat-affected "skin" that is often undesirable on a workpiece surface. Micropulsing also benefits fast-hole EDM applied to silicone-based materials widely used in the semiconductor industry, he says.

As it is, drilling rates for EDM are quite fast. Mr. Beaumont says that a 1-mm hole can penetrate 0.5 inch of Inconel in about 20 seconds. Drilling a 0.020-inch hole through 3/8 inch of a single-crystal alloy may take 15 seconds. The exact times will depend on a variety of factors.

"Micropulsing mainly enhances the hole quality," Mr. Beaumont says. "The major factors contributing to holemaking productivity lie in machine design and automation." The factors he identifies are drilling the metering holes and diffuser shapes in one setup, automatically detecting when the electrode breaks through the exit side of a workpiece, and automatically performing inspection routines to verify that all programmed holes have been completed before the part is removed from the fixture. Multi-axis CNC positioning and automation are also important for minimizing drilling cycle times. On the company’s FH-Series of fast-hole EDM models, workpiece positioning is accomplished by moving five axes simultaneously.

The fast-hole EDM systems from Beaumont Machine were the first to incorporate these capabilities on an integrated machining platform. The company offers these systems as complete turnkey packages because the interaction of process variables in any application requires a custom engineering effort. The micropulse technology is available as an option on new systems. The company is now building large systems to accommodate the massive workpieces commonly found in power generation in addition to machines sized for the aircraft engine and semiconductor

industries.

Related Content

Hybrid Control Makes Lights-Out EDM More Accessible

This CNC enables EDMs to switch between G-code and an integrated CAM system to adapt to changing conditions and make lights-out manufacturing more attainable.

Read MoreMC Machinery Displays EDM, Precision Milling, 3D Printing

IMTS 2024: MC Machinery Systems showcases an array of EDM and precision milling tools, as well as a wire laser metal 3D printer.

Read MoreNew Look, New Feel, New Robots at System 3R

Are AMRs the next big trend in job shop automation? System 3R’s IMTS booth will emphasize both its specialty EDM tooling and its automation products, including an autonomous moving robot.

Read MoreSodick Die-Sinker EDM Fits Range of Automation Needs

The Sodick ALG EDM series doubles motor response speed for the development of accurate, high-quality molds, and is equipped with automated features for continuous operations.

Read MoreRead Next

Aerospace Hole Making Takes Shape

The demand for fast hole making will intensify as more fuel-efficient jet engines are introduced. Electrical discharge machining is emerging as the answer.

Read MoreAMRs Are Moving Into Manufacturing: 4 Considerations for Implementation

AMRs can provide a flexible, easy-to-use automation platform so long as manufacturers choose a suitable task and prepare their facilities.

Read MoreMachine Shop MBA

Making Chips and 91±¬ÁĎÍř are teaming up for a new podcast series called Machine Shop MBA—designed to help manufacturers measure their success against the industry’s best. Through the lens of the 91±¬ÁĎÍř benchmarking program, the series explores the KPIs that set high-performing shops apart, from machine utilization and first-pass yield to employee engagement and revenue per employee.

Read More