New Division, New Product: An Interview with Norgren Workholding

Brent Donaldson of 91±¬ÁĎÍř chats with Corey Shidler of Norgren Workholding on the company's new soft jaw.

Share

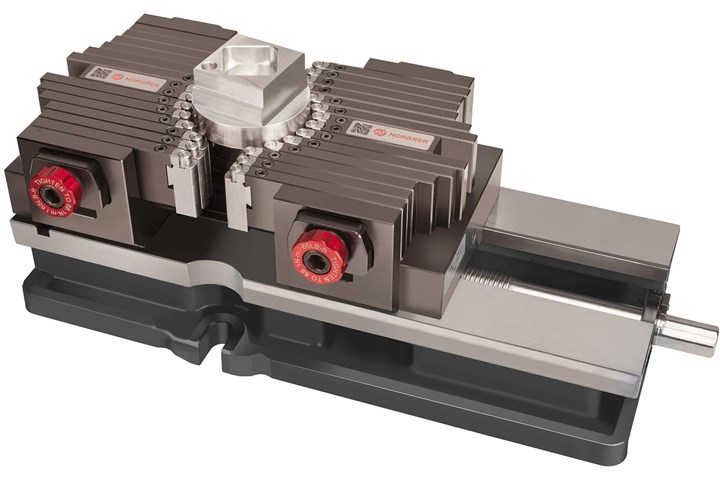

Norgren Workholding, a new division of Norgren, arrives at IMTS with the Adaptix Soft Jaw in tow. Adaptix is Norgen Workholding’s signature and singular product — so far.

Brent Donaldson, executive editor of 91±¬ÁĎÍř, sits down with Corey Shidler, an application engineer at Norgren, to discuss why IMTS is the perfect opportunity to showcase this new division and product.

Brent Donaldson, executive editor of 91±¬ÁĎÍř: Hi Corey. Tell me about what’s new with Norgren as we head into this IMTS.

Corey Shidler, application engineer at Norgren: As Norgren Workholding, we’re a relatively new division with Norgren. We launched in December of last year with our first product: the Adaptix Soft Jaw.

BD: Congratulations. Tell me more about the Adaptix.

CS: Adaptix is our sole product, a workholder. The highlight of this product is it can be dropped onto different vises, such as Schunk, Kurt, etcetera. What makes the Adaptix special is that there are slight differences in the vises its going on, so the mounting pattern must be slightly different as well. We can also do some configurations on tips and studs with the Adaptix. But, as we just launched last year, it’s not like we have 50 products and we’re just highlighting our newest one, like some companies are at the show.

BD: What does it mean for Norgren Workholding to be able to bring the Adaptix to IMTS?

CS: The division of the company and the product are both new items that will be on display this year. It’s important to be able to showcase the innovative spirit of Norgren overall, which is what led to the launch of this division alongside Adaptix. The new division and the design of Adaptix introduces our global clientele to our approach when it comes to innovative manufacturing.

The Adaptix product is designed to offer benefits such as instant setup, elimination of storage, interchangeable pin tips, vise compatibility, durability and field repairability. As opposed to single-application soft jaws, Adaptix is said to solve several machining problems by being able to grip nearly any part with repeatability and noted clamping force. When designing this product, Norgren wanted to bring reduced setup and changeover times, costs and time spent designing, creating and storing vises and soft jaws.

Related Content

-

Briquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.

-

Five Common Mistakes Shops Make with ER Collets (And How to Prevent Them)

Collets play a crucial role in the machining process, so proper tool assembly and maintenance is important. Here are five potential pitfalls to avoid when using ER collets.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.