The Lowdown on Machine Tool Lubricants

Need help choosing the right lubricant for your machine tools and workplace environment? Here’s a resource to help keep your equipment humming along.

Share

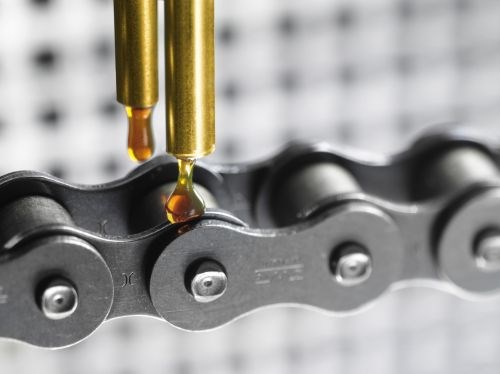

Proper lubrication management is central to the long service life of your machine tools. Choosing the right mix for the type of work you’re doing, as well as the environment you’re doing it in, will pay off in the long run. To aid in selection, Klüber Lubrication has developed a that provides insights for a variety of markets into how the proper lubricant solutions save energy, protect equipment and enhance processes. The kind of information you’ll find includes:

- Product spotlights that describe lubricant properties and areas of likely applications such as couplings, joints and gears.

- Blog overviews from a Klüber expert about special application issues like the advantages of using synthetic ester oils, high viscosity index (VI) base oils or high-performance NSF H1 food-grade lubricants.

- White papers that provide in-depth information about test procedures, lubricant properties and application techniques.

- Case histories that detail successful application in various industries, climates and hazardous environments.

- News releases on the latest developments in lubricant solutions for new applications, government regulations and other timely issues.

Related Content

-

Oelheld Coolant Increases Metal Removal Rates

The odorless coolant is said to offer increased removal rates, lower electrode wear, excellent surface qualities, lower refill quantities and longevity to provide lower overall operating costs.

-

3 Machine Options to Aid Automation

Don’t overlook controller options, process security options and coolant handling when staring down the line items of a new machine purchase.

-

Steco Corp. Coolant Protects Cutting Tools

PMTS 2025: Tap Magic H2OX NC keeps tooling clean and cool while also providing maximum lubricity to protect and prolong the tool life.