Why Machine a Part on a Lathe: February 2017 Digital Edition

The latest issue of 91±¬ÁĎÍř covers topics such as milling on a turning center, risk management and machine monitoring with DNC.

Share

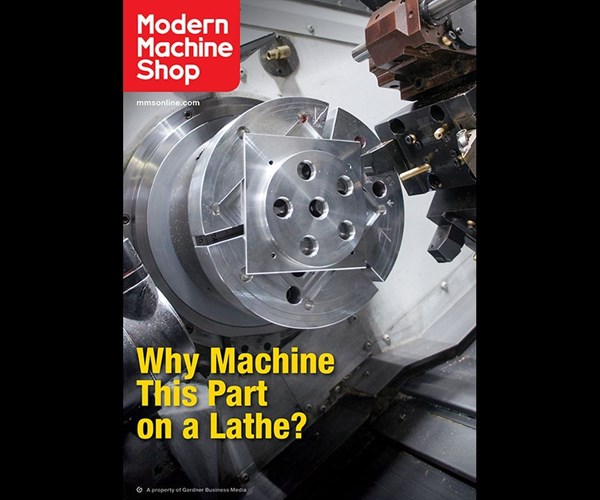

Read the February digital edition by clicking on the photo above.

Versatile machining has turned on options and creativity for one shop that has long thrived on its ability to mill boxy parts on a turning platform. Today, newer technology and techniques enable saying “yes” to more work than ever before. Read the full story on page 68.

Also in this issue:

- The new ISO 9001:2015 standard places greater emphasis on risk management, yet medical shops with ISO 13485 certification already manage this.

- A growth path for DNC, the network for distributing part programs to CNC machines, could be to use it as a springboard for machine monitoring and data collection.

- How a one-hand, quick-change vise maximizes freedom for soft jaws.

- A product spotlight on machining centers.

Access these stories and more in our February 2017 digital edition.

Related Content

-

How to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

-

4 Manufacturing Trends That Cannot Be Ignored

The next five years will present their own unique set of challenges, and shops can alleviate them by embracing these technologies and trends.

-

6 Variations That Kill Productivity

The act of qualifying CNC programs is largely related to eliminating variations, which can be a daunting task when you consider how many things can change from one time a job is run to the next.