How Machine Tools Can Save Energy

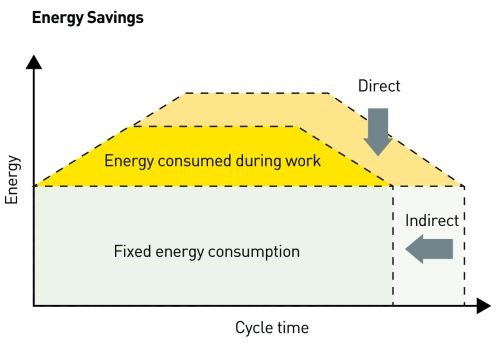

It starts with energy-efficient designs of the servo and spindle systems. This article introduces useful concepts such as the difference between direct and indirect energy consumption.

Share

Energy usage is becoming a more important factor in determining the overall efficiency of automation systems, including CNC machine tools. Conserving energy cuts costs and protects the environment. An article by Paul Webster, engineering manager at FANUC FA America, explores the topic and focuses on the value of modern electrical motor design for CNC machine tools, injection machines and other automated production equipment. “Energy Saving Designs in Factory Automation Equipment” also introduces a number of key concepts in energy consumption and efficiency strategies.

Related Content

-

Using Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

-

Using Automation to Reduce COGS and Stay Globally Competitive

Decade-long, multiphase automation investments lower operating costs and maintain technology lead in an increasingly competitive global market.

-

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.