Share

This content originally appeared on our sister brand, Additive Manufacturing Media. Get articles, podcasts and loads more AM content at .

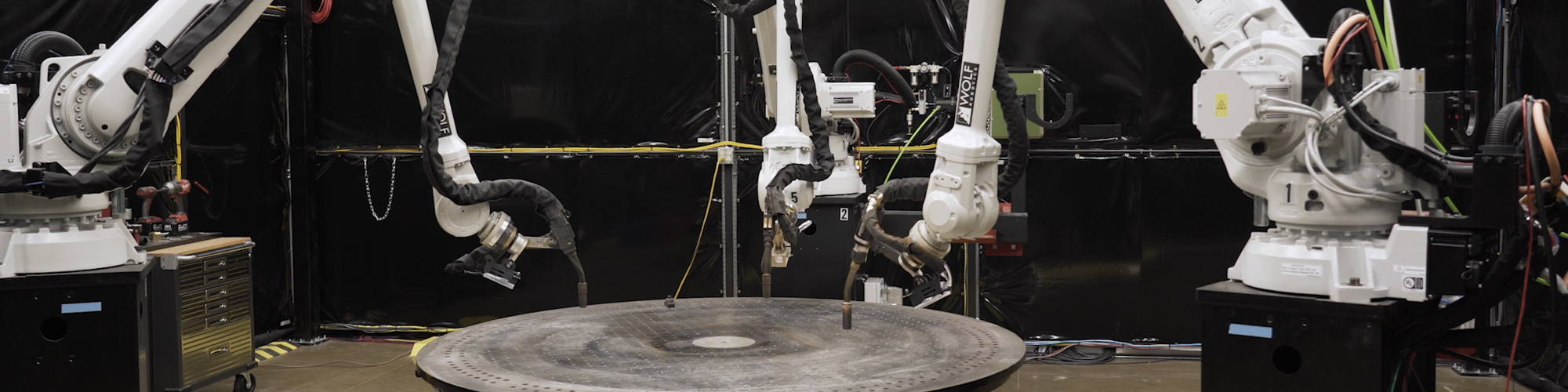

When robots perform deposition-style 3D printing, adding more robots offers the chance to build large parts faster. The Medusa system developed at Oak Ridge National Laboratory’s Manufacturing Demonstration Facility combines three robots performing directed energy deposition (DED) metal additive manufacturing via Lincoln Electric Additive Solutions’ wire arc additive manufacturing process. The robots apply material in synchronized motion around a shared indexing turntable, and future versions of the system will add even more robots.

Related resources:

- Oak Ridge National Laboratory

- The way ahead for

- Why additive manufacturing and robots

- Another example of

Related Content

-

Same Headcount, Double the Sales: Successful Job Shop Automation

Doubling sales requires more than just robots. Pro Products’ staff works in tandem with robots, performing inspection and other value-added activities.

-

Which Approach to Automation Fits Your CNC Machine Tool?

Choosing the right automation to pair with a CNC machine tool cell means weighing various factors, as this fabrication business has learned well.

-

Studer's Automation, Entry-Level Solutions Take Center Stage

At its 2024 Music Motion Meeting, Studer AG showed off its entry-level line of grinding machines, as well as its newest universal loading system.