The Evolution of the Retention Pin

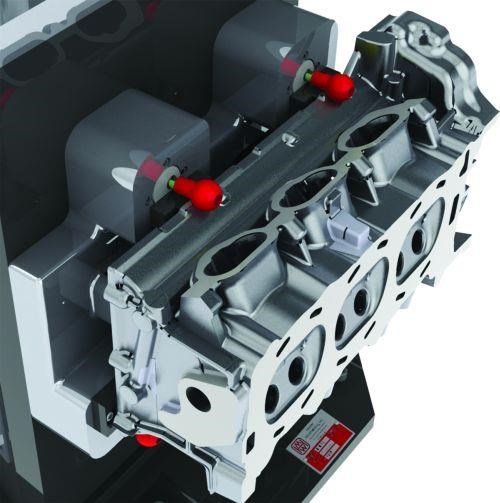

A new retention pin design enables the spring-loaded workholding devices to do more than simply ease part loading. They can clamp parts, too.

Share

Over the years, spring-loaded retention pin designs have evolved. Traditionally, they have helped users locate a part on a fixture and hold it in place before actuating swing or link clamps that secure the part for machining. However, this new version from Master Workholding includes a hydraulic circuit enabling the devices to function as clamps, too.

Related Content

-

Shop Reclaims 10,000 Square Feet with Inventory Management System

Intech Athens’ inventory management system, which includes vertical lift modules from Kardex Remstar and tool management software from ZOLLER, has saved the company time, space and money.

-

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.

-

Briquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.