What is Laser Cleaning? How Does it Work? EMAG Experts Explain

Lasers provide the flexibility to clean some areas of a CNC-machined workpiece while leaving others untouched.

Share

Video courtesy of EMAG LaserTec

We tend to think of cleaning as a process involving fluid, detergent and abrasion — but can a beam of light clean a part?

Welcome! You鈥檝e unlocked premium content.

On a laser cleaning machine, the light beam becomes a tool, vaporizing dust and other particles without marring the workpiece surface. To learn more, I reached out to Konrad Eibl, an application engineer and North American sales coordinator for EMAG LaserTec, and Melanie Mangang, who works in the company’s applications department.

What is Laser Cleaning?

Laser cleaning is ideal for targeting specific areas of a workpiece while leaving others untouched.

Laser cleaning is an ablation process. S锘縣ort, high-energy pulses vaporize oil, oxides, paint and other residuals for extraction with a vacuuming device.

Primary applications include preparation for joining or bonding processes, the removal of coatings like paint or phosphate layers and the cleaning of die cast dies.

There are three main pieces of equipment used for laser cleaning: a solid-state laser source such as a fiber laser, a 2D scanner and a fume extraction unit.

Internal components of EMAG LaserTec cleaning machines include a fume extraction unit needed to vacuum out material removed during the laser cleaning process.

Laser cleaning is a technical process that is used to get defined surfaces on a workpiece to reach a specified level of cleanliness. This photo shows the inside of an EMAG LaserTec laser cleaning machine. Photo Credit: EMAG LaserTec

What Are the Benefits and Challenges of Laser Cleaning?

Laser cleaning can be more flexible than washing and other traditional cleaning methods because specifications like beam geometry and power are easily adjustable. Depending on the material and properties, parameters can be adjusted to affect things like pulse duration and power. It is best used for processing metals, as Eibl and Mangang said. Iron-based materials, for example, usually don’t present any sort of challenge for laser cleaning machines.

The primary advantage is energy efficiency. Although pulse power is high, pulses are short, which keeps the average power relatively low. Laser cleaning equipment also requires little maintenance, which can be as simple as checking ventilation equipment for contamination or airflow blockage and inspecting the machine for dust, debris and other contaminants.

Laser cleaning can work well with a variety of materials, making it a versatile cleaning method.

The primary limitation is the amount of contamination. Laser cleaning can’t remove materials like chips or other larger particles.

This photo shows the inside of an EMAG LaserTec laser cleaning machine, including the fume extraction unit needed to vacuum out material removed during the laser cleaning process.

Photo Credit: EMAG LaserTec

Visual inspection tends to work well for checking coated or painted surfaces for contamination. Measuring surface energy and fluorescence works well for checking liquid contamination. Surface wettability checks and investigations of chemical composition can also reveal contamination.

Here’s a summary of the benefits of laser cleaning compared to other cleaning methods:

- The process is ideal for local cleaning and de-coating within a well-defined area.

- No drying is required because there is no fluid or detergent involved.

- Automating and integrating the equipment into manufacturing lines is easy. Depending on software complexity, training to use laser cleaning machines can take as little as a day or two.

- Little maintenance is required. Visual inspection and checking for dust and debris are the primary maintenance methods required to keep these machines operating smoothly.

- Low energy usage makes the process economical in the long run. In comparison to a traditional washing machine, laser cleaning machines occupy less space on the shop floor, and the energy consumption can be as low as a few kilowatt-hours.

Related Content

How to Meet Aerospace’s Material Challenges and More at IMTS

Succeeding in aerospace manufacturing requires high-performing processes paired with high-performance machine tools. IMTS can help you find both.

Read MoreHow to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

Read More4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

Read MoreObscure CNC Features That Can Help (or Hurt) You

You cannot begin to take advantage of an available feature if you do not know it exists. Conversely, you will not know how to avoid CNC features that may be detrimental to your process.

Read MoreRead Next

Machining 101: What are Machining Centers?

Machining centers offer a wide range of possible operations, but that adaptability comes with the need to stay flexible and perform successful measurements at all times.

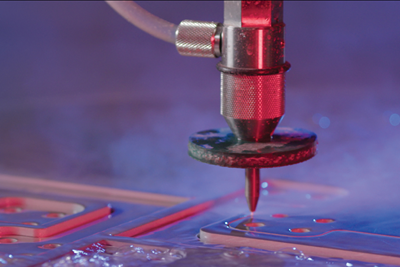

Read MoreMachining 101: What is Waterjet Cutting?

Waterjet cutting may be a simpler machining method, but it packs a powerful punch that requires operators to stay cognizant of multiple parts’ wear and accuracy.

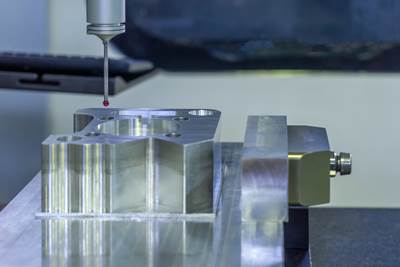

Read MoreMachining 101: What Are Coordinate Measuring Machines?

Optimized bases, drives, probes, software and more make coordinate measuring machines the most accurate tools for measuring part dimensions.

Read More