-

SPONSORED

-

SPONSORED

-

Columns

The Starting Point for Machine Tool Monitoring: Data Analysis Is an Emotional Choice

For machine shops, the transformation that data-driven manufacturing promises to bring begins with machine monitoring, and there is a human component to this.

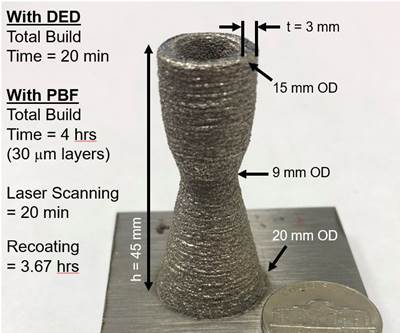

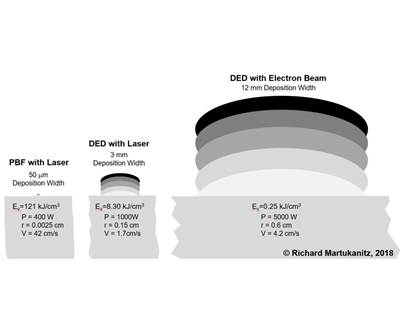

Read MoreWhat Is Directed Energy Deposition?

Analyzing directed energy deposition and powder-bed fusion provides a thorough understanding of the extra machining necessary for a “near net shape” versus a “net shape” manufacturing process.

Read MoreSetting a Roughness Goal and Meeting It

Subjective surface finishes have no place in today’s high-precision manufacturing environment.

Read MoreThe Sign on the Wall When I First Met Mark Albert: “When In Doubt, Tell the Truth”

Not just writing, but writing with integrity, is the work and the craft to which Mark Albert gave his career.

Read MoreImproving Program Compatibility Among Your CNCs

Put in the effort to eliminate machine-specific programming methods.

Read MoreDial vs. Test Indicators

Dial and test indicators are close cousins. They are both mechanical magnifying devices used for dimensional comparison.

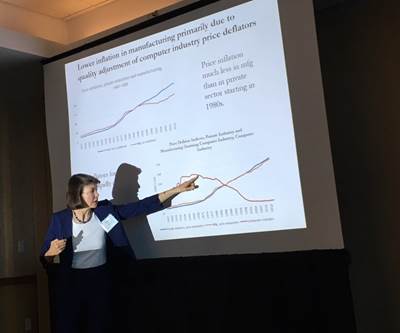

Read MoreHow We Misread Productivity Gains in the Debate About Manufacturing Jobs

Manufacturing appears to lead other sectors in productivity growth, but productivity measures pick up factors besides automation. Recognizing this fact changes the terms of part of the public debate.

Read MoreAdditive Manufacturing for Large Parts

Powder-bed fusion is driving the hype for additive manufacturing right now, but it may not be the best answer. Directed energy deposition is a strong contender.

Read MoreUnderstanding CNC Machine Accuracy and Repeatability

Properly evaluating machine tool capability requires understanding how the both user and the builder can influence precision.

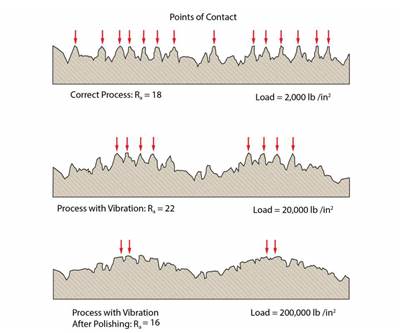

Read MoreWhat Do Manufacturers Really Know About the Surfaces of the Parts They Are Producing?

Knowing only the average roughness may not be enough. Other surface parameters can affect product quality.

Read MoreJust This Once, You Can Blame the Gage

Even the old, reliable gage is subject to wear. George Schuetz, director of precision gages at Mahr inc., gives guidance for machinists to maintain their gages.

Read More