Automated and 3D Technology Innovates Welding

Automated arc welding, 3D laser welding, 3D laser marking and additive manufacturing are all a part of Trumpf's lineup.

Share

Trumpf Inc. showcases its latest in automated arc welding, 3D laser welding, 3D laser marking, and additive manufacturing technology. Trumpf highlights the TruArc Weld 1000, an automated arc welding system designed for easy and affordable high-mix, low-volume production, and its laser technology for 3D processing, including the TruLaser Station 7000 fiber, a versatile, compact and fully-equipped low-investment 3D laser welding system. In addition, it also presents a TruMarkStation 7000 with a TruMark 6030 marking laser for high-performance 3D laser marking.

The TruArc Weld 1000, Trumpf’s automated arc welding system, makes it easy for fabricators to get started in automated welding, according to the company. For affordable high-mix, low-volume production, the TruArc Weld 1000 is the perfect solution. A collaborative robot, or “cobot,” are designed to make solutions easy to program and weld in just minutes. Even first-time operators can program by simply guiding the cobot by hand.

Programming is greatly simplified by the operating unit on the welding torch and factory settings for different materials and sheet thicknesses. Thanks to the rapid programming, fabricators can provide a cost-effective means of tackling short production and single-part runs. Trumpf says overall the TruArc Weld 1000 creates a process that is more efficient than manual welding and produces a high-quality weld seam.

TruLaser Station 7000 is a versatile, compact and fully equipped low-investment 3D laser welding system. The higher power laser enables a broad range of applications. The TruLaser Station 7000 is to designed facilitate efficient and ergonomic 3D laser welding of small assemblies, such as sensors, rotationally symmetrical components and medical devices. According to Trumpf, the large work area also makes it possible to integrate fixtures and process larger components in a small installation area. Fully integrated image processing ensures reliable weld seam positioning.

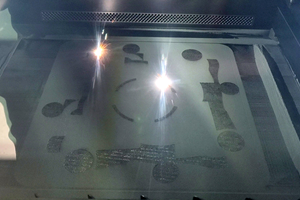

Trumpf demonstrates laser marking of 3D metal printed parts with a TruMark Station 7000 laser marking station that features a TruMark 6030 marking laser and VisionLine 3 feature recognition capability. The TruMark 6030 is a high-performance marking laser with 3D functionality. The laser’s beam quality and high power densities promote clean material removal and high-contrast markings. The TruMark 6030 can be integrated into production systems quickly and easily.

Trumpf’s second exhibit in the Additive Manufacturing pavilion at IMTS 2022 is about its laser 3D printing technology. Trumpf features the TruPrint Green Edition, a highly productive metal additive manufacturing laser machine designed for specialized applications, including the 3D printing of copper, copper alloys, gold and other precious metals. There is also a virtual showroom for participants to take a deep dive into the variety of laser technology and AM applications offered by Trumpf.

The TruPrint Green Edition is a highly productive metal additive manufacturing laser machine designed for specialized applications including the 3D printing of copper, copper alloys, gold and other precious metals. With a wavelength of 515 nm, the TruDisk 1020 green laser makes it possible to 3D print highly reflective materials such as copper, which can be extremely difficult or impossible to process with infrared wavelengths.

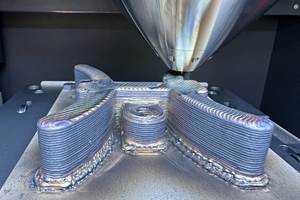

The TruPrint Green Edition can also manufacture parts made of copper alloys such as CuCr1Zr with a larger process window and higher productivity than traditional infrared laser metal fusion laser systems. In addition, Trumpf displays parts that demonstrate its laser metal deposition (LMD) and laser metal fusion (LMF) applications for the aerospace, space, medical industries.

Related Content

Push-Button DED System Aims for Machine Shop Workflow in Metal Additive Manufacturing

Meltio M600 metal 3D printer employs probing, quick-change workholding and wire material stock to permit production in coordination with CNC machines.

Read More6 Trends in Additive Manufacturing Technology

IMTS 2024 features a larger Additive Manufacturing Pavilion than ever before, with veteran suppliers alongside startups and newcomers at the front of the West Building. As you browse these exhibitors, as well as booths found elsewhere at the show, keep an eye out for these trends in AM.

Read MoreJTEKT Technology Days Showcases Synergies

The event took place following the company’s completion of its new showroom and decision to merge several of its brands under the JTEKT name.

Read MoreDigital Thread Enables First-Time-Right 3D Printing

Connecting all stages of manufacturing, from design to postprocessing, helps break down barriers to industrializing additive manufacturing.

Read MoreRead Next

How I Made It: Dennis Rymanowski

Dennis Rymanowski has worked at NSH USA for 60 years, with his passion for manufacturing living alongside his passion for his family’s polka band.

Read MoreA New Frontier in Surface Finish Control

What if your machine tool could measure surface roughness as it cuts? This article explores how in-process metrology is advancing from concept to reality, enabling real-time feedback, immediate detection of anomalies and new levels of control over surface quality. Discover the technologies making this possible.

Read More