-

SPONSORED

-

SPONSORED

-

-

Turn/Mill

Turning Center Features Three Y-Axis Turrets

According to the company, the Super NTY3 multitasking turning center offers stock-on turning and machining that virtually eliminates productivity lost as a result of tool changes. Three turrets, each with a Y axis, allow complete turning/machining/finishing in one pass to reduce cycle times.

Read MoreTurning Is Optional

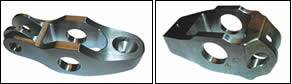

The part requires only milling and drilling, but it is still run on a lathe. Except for the cutoff tool, all of the turret positions on this lathe hold rotating tools. In other words, turning is not essential for using a lathe effectively. This application illustrates the productive possibilities of a modern turn-mill machine.

Read MoreMultitasking With A Small Footprint

The Integrex i-150 shows how a multitasking machine for small precision parts can combine done-in-one process with a compact structure to reduce floor space requirements. Most multitasking machines for parts of this size use a second spindle for endworking of parts after cutoff. This machine uses a swing-away workholding device instead.

Read MoreIt Begins With Belief

This shop’s approach to unattended machining focuses on the big picture.

Read MoreContinuous Turning On Turn-Mills

A new CAM feature continuously manages B-axis head rotation to allow turn-mills to completely turn inner and outer workpiece profiles using a single tool.

Read MoreTurn, Mill And Laser-Harden In One Setup

A new turn-mill platform combines turning and four-axis milling with integral laser hardening and laser welding in one workpiece setup. This enables shops to bring often-outsourced laser treatment in-house to reduce lead times.

Read MoreMilling Chuck Pumps Up Productivity

Rigid toolholding offers a platform for productivity on this pump manufacturer's mill-turn center.

Read More