Bow Machining I

Toyoda's Stealth vertical machining center is part of a manufacturing process that bow maker Mathews Inc. uses to produce 300,000 bows per year.

Share

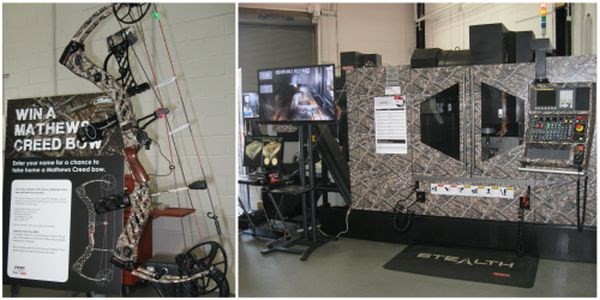

Toyoda's Stealth vertical machining center is part of a manufacturing process that bow maker Mathews Inc. uses to produce 300,000 bows per year. The machine is used to rapidly mill out the many pockets in the honeycomb-like form giving the bow its light weight. At its “Toyotech” event last week—an open house with both machining demos and technology seminars—Toyoda had the machine painted in hunting camouflage to draw attention to Mathews’ success with this VMC.

Coincidentally, this was one of two bows featured at simultaneous events by Chicago-area machine tool companies. Read about the other.

Over a dozen machine tools were on display and/or running demos at the event,

include various large machines and systems. This flexible manufacturing system

was an example.

Related Content

-

Quick-Change Tool Heads Reduce Setup on Swiss-Type Turning Centers

This new quick-change tooling system enables shops to get more production from their Swiss turning centers through reduced tool setup time and matches the performance of a solid tool.

-

How to Determine the Currently Active Work Offset Number

Determining the currently active work offset number is practical when the program zero point is changing between workpieces in a production run.

-

How to Successfully Adopt Five-Axis Machining

While there are many changes to adopt when moving to five-axis, they all compliment the overall goal of better parts through less operations.