Gosiger Adds 3D Printing Equipment, Services via Stratasys

The technology provider and integrator is helping to bring 3D printing to the shop floor via a new product line and partnership.

Share

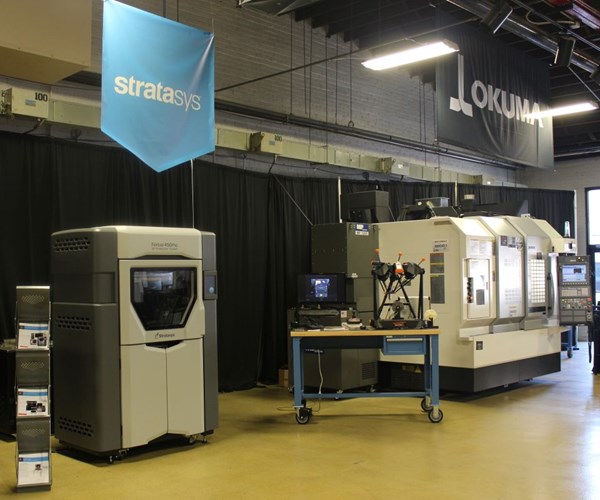

Machine tool distributor and systems integration expert Gosiger recently announced a new agreement to supply and service Stratasys 3D printers. The move is a natural advance for the company, whose customers are increasingly showing interest in additive manufacturing. However, the move is also strategic on the part of the 3D-printing equipment builder. Stratasys sees the future of its equipment not primarily among home or hobbyist users (though that might be a part of it) but instead in manufacturing facilities. The goal—for both Gosiger and Stratasys—is to help advance AM into applications out on the shop floor, and even into production.

As Josh Claman, chief business officer for Stratasys, put it: “The history of 3D printing is design and prototyping. The future is that, plus manufacturing.”

Claman addressed an audience at 3D4U, an event hosted at Gosiger’s Dayton, Ohio, headquarters shortly after the initial announcement was made. The June 14 open house and keynote presentation was a chance for Gosiger customers to learn about Stratasys technology as well as an opportunity for Stratasys to articulate its vision for additive manufacturing as a valuable tool for shopfloor applications as well as design and prototyping functions. Partnering with Gosiger provides necessary relationships and manufacturing expertise to help achieve that vision.

From Gosiger’s perspective, supplying 3D printing equipment is another way to serve its customers in addition to the machine tools, robotics, inspection equipment and complete turnkey systems it already provides. The company also sees great potential for using its own Stratasys machines to produce custom objects for its clients such as jigs and fixtures.

“As we expose our engineers to this technology, they are coming up with new ideas daily,” says John Haley, Gosiger CEO.

A number of sample components were on display during the 3D4U event, including some from Stratasys, but also many that were created by Gosiger employees following training on Stratasys 3D printers. These parts illustrate some of the services that Gosiger can provide with its new 3D printing capacity—and they may inspire customers to seek 3D printers of their own. A few examples of these applications are pictured below:

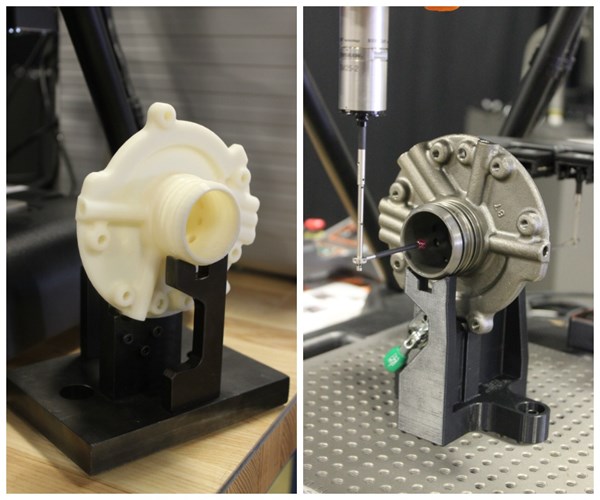

Gosiger frequently supplies machined custom fixtures for workholding and inspection. A metal CMM fixture such as the one on the left (holding the 3D-printed model stator) might cost upwards of $600 and take a week at a machine shop. The 3D-printed fixture (on the right) cost only $82 and was produced within a day on a Stratasys 450mc.

Robotic arms are another key component that Gosiger supplies, often as part of larger robot-tended cells. Custom grippers tailored to the customer’s application are commonly part of the package. Tools such as vacuum end effectors (like the one on the left) and jawed grippers (right) can be created and produced faster and more cost-effectively with a 3D printer than they can be machined. As an added benefit, they are also lighter than machined grippers.

1.3D-printed models can help speed the setup of CMMs and other systems. This model of an injection-molded vacuum cleaner component as well as the fixture it is resting on were 3D printed so that a CMM could be programmed before the actual parts arrived, reducing the quality control setup time from about a month to just one day.

Related Content

In Moldmaking, Mantle Process Addresses Lead Time and Talent Pool

A new process delivered through what looks like a standard machining center promises to streamline machining of injection mold cores and cavities and even answer the declining availability of toolmakers.

Read MoreAdditive/Subtractive Hybrid CNC Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read MoreMachine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

Read MoreHow to Meet Aerospace’s Material Challenges and More at IMTS

Succeeding in aerospace manufacturing requires high-performing processes paired with high-performance machine tools. IMTS can help you find both.

Read MoreRead Next

How I Made It: Dennis Rymanowski

Dennis Rymanowski has worked at NSH USA for 60 years, with his passion for manufacturing living alongside his passion for his family’s polka band.

Read MoreA New Frontier in Surface Finish Control

What if your machine tool could measure surface roughness as it cuts? This article explores how in-process metrology is advancing from concept to reality, enabling real-time feedback, immediate detection of anomalies and new levels of control over surface quality. Discover the technologies making this possible.

Read More.jpg;width=70;height=70;mode=crop)