Learn How Additive Manufacturing Will Change Production at AM In-Depth

3D printing will change how parts and products are manufactured. Get a front-row seat at this free educational series running through IMTS Spark.

Share

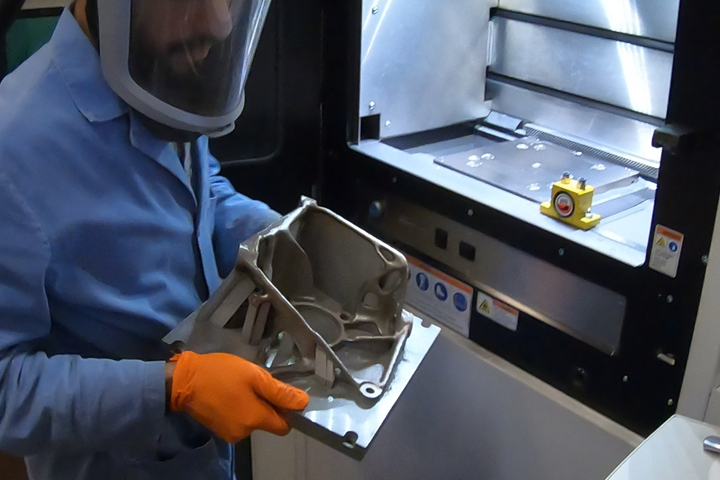

3D printing is a viable production technology, but it’s never as simple as just pressing “Print.” That’s why we more frequently use the term “additive manufacturing,” which encompasses not just the manufacturing method, but the design, postprocessing, quality assurance and other activities necessary for 3D printing to function in a production environment.

Hitting “print” is only a small part of additive manufacturing. Presentations at AM In-Depth will dive into issues like design and quality assurance across the full AM workflow.

That’s also part of the vision behind AM In-Depth, a free education series offered as part of IMTS Spark. This series explores the realities of 3D printing for production, from changing the engineer’s mindset about design all the way through benchmarking machines from different builders to ensure repeatable success.

AM In-Depth will run Monday, Wednesday and Friday the weeks of September 21 and 28. Two sessions are scheduled each day, beginning at noon and 1:30 p.m. CDT. Each session is moderated by an Additive Manufacturing editor and presented by AM users and experts. Speakers will share real-world applications and discuss the roadblocks overcome to get there. Find the complete schedule on IMTS.com/spark.

A partial list of topics is included below. Click “More” to view the summary and speaker details, and use the “Add to MySpark Planner” button in the upper right of each session page to add sessions to your agenda and get access to the livestream.

- Serial production of plastic parts industry.

- The construction of a new spacecraft propulsion system made possible through metal AM.

- How engineering teams should think differently about design for AM (presented by frequent MMS contributor Tim Simpson).

- The use of 3D printing for building mission-critical turbomachinery parts.

- Benchmarking AM systems from different builders to ensure repeatable quality.

- Designing 3D printed parts with biological structures

- Metrology and characterization from metal powder through final part performance

Related Content

-

The Downloadable Metal 3D Printer

Copenhagen researchers introduce a fully open-source laser powder bed fusion system, now available on GitHub. This release follows their development of an open-source vat polymerization machine. Here is the purpose and promise of this philanthropically funded effort to advance additive manufacturing application and adoption.

-

OEMs Showcase Hybrid Manufacturing Applications

Mazak and Mastercam worked together to demonstrate the viability of hybrid additive/subtractive machining techniques at a recent event held in Florence, Kentucky.

-

How to Meet Aerospace’s Material Challenges and More at IMTS

Succeeding in aerospace manufacturing requires high-performing processes paired with high-performance machine tools. IMTS can help you find both.

.jpg;width=70;height=70;mode=crop)