Share

Marposs’ 60th-anniversary open house started with presentations from President Ed Vella and Vice President Francesco Fussi, who each discussed the future direction of Marposs as it focuses on growth across several industries, including the EV and semiconductor sectors.

During its September open house in Auburn Hills, Michigan, Marposs celebrated its 60th anniversary of business in North America. While taking the time to recognize and celebrate its past, the company turned its eye toward the future, spotlighting new opportunities in the EV and semiconductor sectors, among others.

“EV is a transition that has ramped up in the last three or four years in the United States,” says Marposs President Ed Vella. “Fifty percent of our business is in the EV sector.”

While Vella says Marposs is still committed to its business in the internal combustion engines (ICE) market, Marposs displayed its inspection and testing solutions for several markets that are growing in the U.S., such as semiconductors and EVs, during the open house.

Semiconductor Solutions

One of the ways Marposs has expanded its presence in the aforementioned sectors is through acquisitions. Marposs has done business in the semiconductor sector since 1980, but its 2019 acquisition of Stil enabled the company to expand its non-contact distance measurement solutions for the market, bringing Stil products and technology into the Marposs family. Stil’s founders developed chromatic confocal technology, which uses a chromatic lens and wavelengths of visual light to produce a color-coded measurement of the distance to a surface.

With this technology, Marposs produces sensors like the MPLS-DM, with 180 measuring points aligned along a range of 1-to-12 millimeters. These sensors measure any material capable of reflecting white light, making them helpful in determining wafer thickness during the semiconductor manufacturing process.

EV Battery Solutions

With the focused expansion of its presence in the EV market, Marposs showcased some of its products used in this growing sector. One of these products is the Leak B-Tracer. This machine detects the leaking of volatile organic compounds (VOCs) from sealed battery cells in a vacuum chamber, with a cycle time between 15 seconds and one minute.

Shown in the video above, the Leak B-Tracer includes two removable bottom trays, enabling retooling for different cell formats, as well as a pneumatically actuated horizontal slide for moving the bottom trays from left to right.

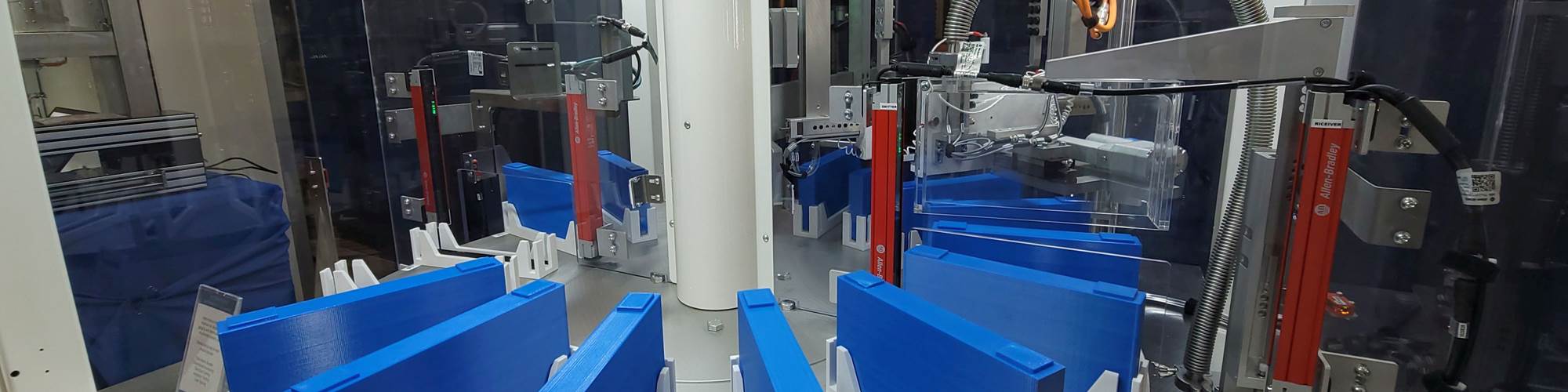

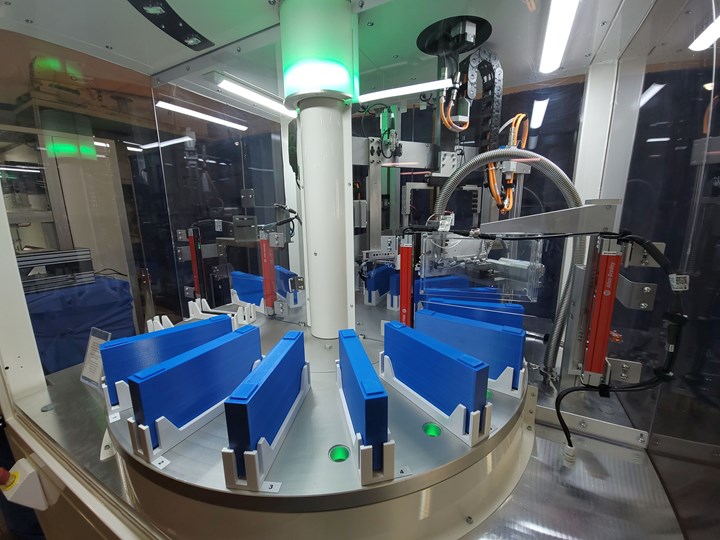

Marposs also displayed its Elettrosystem automatic machine for prismatic battery cell testing. Operators or robots can load up to 18 cells into the multistation measuring machine at once. The machine then performs leak testing, dimension inspections and electrical testing. Marposs added this machine to its catalog after acquiring Italian company Elettrosystem in 2018.

The multistation measuring machine features a turntable bench that moves between the operator side for part unloading and loading, and the measuring and testing stations that perform leak tests, dimension inspections and electrical testing.

With the acquisitions of companies like Elettrosystem, Stil and several other providers of inspection and testing solutions, Marposs has added measurement and inspection equipment to its repertoire. This aligns with Marposs’ stated goals during the open house: diversifying its approach to sustain future growth. The company’s expanding presence in the EV and semiconductor markets have only made Vella and the rest of Marposs more confident in its future path.

“What excites me is in reality, technology is moving pretty quickly, so when the technology is evolving — and right now it’s a fast-paced evolution — and that’s not only Marposs technology but our customers’ technology, they’re coming up with new problems to address in this evolving manufacturing environment,” Vella says. “It gives us an opportunity to be innovative and come up with new solutions. Right now, what’s exciting is we have a very stimulating environment.”

Related Content

Process Control — Leveraging Machine Shop Connectivity in Real Time

Renishaw Central, the company’s new end-to-end process control software, offers a new methodology for producing families of parts through actionable data.

Read MoreThe Many Ways of Measuring Thickness

While it may seem to be a straightforward check, there are many approaches to measuring thickness that are determined by the requirements of the part.

Read MoreHow to Evaluate Measurement Uncertainty

Manufacturing and measurement are closely coupled. An important consideration for the use of measurement results is the associated measurement uncertainty. This article describes common metrology terms and provides an example uncertainty analysis.

Read MoreTurning Fixed-Body Plug Gages Inside Out

Fixed-body mechanical plug gages provide fast, high-performance measurement for tight-tolerance holes.

Read MoreRead Next

A New Frontier in Surface Finish Control

What if your machine tool could measure surface roughness as it cuts? This article explores how in-process metrology is advancing from concept to reality, enabling real-time feedback, immediate detection of anomalies and new levels of control over surface quality. Discover the technologies making this possible.

Read MoreHow I Made It: Dennis Rymanowski

Dennis Rymanowski has worked at NSH USA for 60 years, with his passion for manufacturing living alongside his passion for his family’s polka band.

Read More