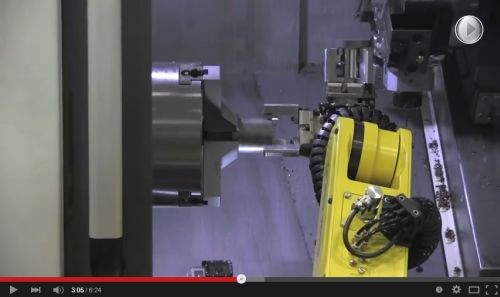

Video: Robot Flipping System for Turning

This video demonstrates how robot flipping station can serve the same purpose as a subspindle on a one-spindle multitasking center.

Share

A lathe or multitasking center equipped with both a main spindle and subspindle enables turned parts to be machined on both ends in one setup, by simply passing the bar from one spindle to the other. But what if you don’t have a subspindle? A robot flipping system can be a cost-effective automated solution.

The video above from Methods Machine Tools shows a Nakamura AS-200 multitasking machine equipped with a FANUC LR Mate 200iD7L robotic arm with two sets of grippers. Around 3:06 in the video, the robot removes the first workpiece, swaps in a blank, then sets the first workpiece unmachined-side down on a shelf just to the left of the machine door. The robot then grasps the part from underneath, flipping it over to be placed back in the spindle for machining on the other end. The configuration enables a two-spindle process to be completed with just one spindle on a smaller machine.

Related Content

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

-

Ballbar Testing Benefits Low-Volume Manufacturing

Thanks to ballbar testing with a Renishaw QC20-W, the Autodesk Technology Centers now have more confidence in their machine tools.

.jpg;width=70;height=70;mode=crop)