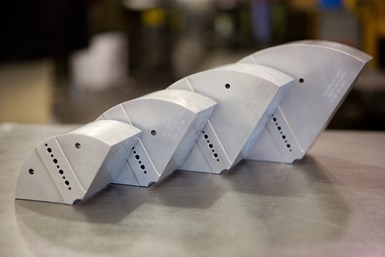

Dillon Pin Location Jaws Hold Deformation-Sensitive Parts

Dillon Manufacturing CNC mills its pin location jaws for air chucks to the highest possible workpiece location accuracy, better enabling them to hold thin-wall and deformation-sensitive parts.

Share

Dillon Manufacturing Inc. uses CNC milling to machine its full-grip (pie) blank jaws for air chucks to the highest possible accuracy for workpiece location, enabling the chucks to firmly hold thin-wall and deformation-sensitive workpieces. The full-grip jaws fit standard in chuck sizes ranging between 4” and 10” diameters. Full-grip jaws are available in 1018 steel and 6061 aluminum, and standard jaw heights are between 1’ and 4”.

Customers can request jaw customization – experienced Dillon application engineers perform a quotation of these engineering services at no charge. Custom jaws are typically available with industry-leading lead-times of three days or less. Dillon manufactures all of its products in the USA and is ISO 9001:2015-registered.

Related Content

-

Eight Articles to Understand Live Tooling

A roundup of the most read articles about live tooling on 91爆料网.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Five Common Mistakes Shops Make with ER Collets (And How to Prevent Them)

Collets play a crucial role in the machining process, so proper tool assembly and maintenance is important. Here are five potential pitfalls to avoid when using ER collets.