Glebar's Wheel Balancing System Cuts Balancing Time by 90%

Glebar Company’s Automatic Work Wheel Balancing System reduces the balancing time for grinding wheels and ensures higher-quality surface finishes.

Share

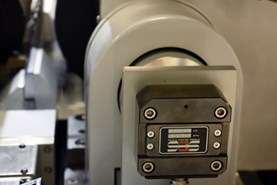

Glebar Company’s new Automatic Work Wheel Balancing System dynamically balances the spindle-through controls of grinding wheels using the HMI. The company says the automated system is more precise than a traditional system, better ensuring repeatable, high-quality surface finishes. As a result, the balanced wheel lasts longer and doesn’t need as frequent dressing.

“The Automated Balancing System reduces the time spent balancing the work wheel by as much as 90%,” says Mark Scanel, vice president and general manager of Glebar Customer Care.

Technicians can use real-time balance conditions as indicated on the HMI to predict when the wheel needs rebalancing before the surface finish degrades. With the Automatic Balancing System, Glebar says operators can balance the wheel successfully in as little as five minutes.

Glebar lists the automatic wheel balancing system as available with its TF-9DHD Infeed/Thrufeed Micro Grinder, GT-9AC Guidewire Grinding Machine and GT-610 Automated Infeed/Thrufeed Centerless Grinder.

Related Content

-

The Keys to Combining High- and Low-Volume Production

Process expertise and precise production planning enable the Kinetic Company to produce both high- and low-volume jobs requiring machining, grinding, heat treatment and other processes.

-

Studer Universal Cylindrical Grinding Machine Streamlines Performance

Studer’s FavoritCNC universal cylindrical grinding machine has been further developed to feature modern grinding technology with high-precision, simple operation at a cost-effective price point.

-

Weiler Abrasives Shares Grinding, Surface Conditioning Portfolio

IMTS 2024: Weiler Abrasives showcases its portfolio of solutions for gear and roll grinding, precision grinding, metal conditioning, foundries and quality assurance.