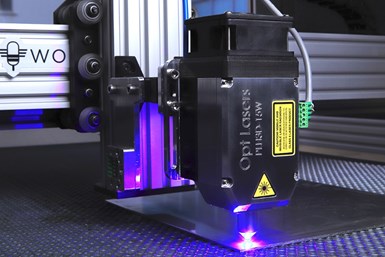

Opt Lasers' PLH3D-15W Blue-Laser Head Boosts Efficiency

Opt Lasers’ PLH3D-15W uses three high-efficiency, blue-laser diodes to provide powerful, sustainable laser processing capabilities.

Share

says its PLH3D-15W is the world’s first compact three-laser-diode laser head for CNC machines, and that most laser-cut or engraved materials better absorb the 445-nm light from its blue laser diodes than light from IR lasers. This increased efficiency lowers the power needed to laser process materials.

The PLH3D-15W uses 6-W laser diodes from Nichia, keeping the diodes at the proper current to reach what Opt Lasers says is an average lifetime of over 20,000 working hours at 6 W of optical power and 25°C. Due to the structure of the laser module, the three lasers use a total of 15 W.

Opt Lasers says its PLH3D-15W uses durable, industrial-grade components, including a 3D-printed air chamber. The company also says its compact laser head is compatible with most CNC machines and integrates with larger systems.

“The industrial market has been lacking the capabilities of highly efficient compact lasers for marking, engraving or cutting,” says Mateuz SzymaÅ„ski, CEO of Opt Lasers. “Available options have focused on single, high-power laser sources reaching higher and higher material processing speeds. This approach was required due to existing technology and the low absorption of the laser wavelength. Multi-point processing has been the fastest solution in many production lines, but was not economical with the use of current laser technology.

“Opt Lasers creates the possibility of changing the industry by using short-wavelength blue laser heads,” SzymaÅ„ski continues. “High absorption of light, low power consumption, low maintenance cost and a size that fits in the palm of your hand makes our compact laser heads an out-of-the-box solution in the production industry.”

PLH3D-15W can cut or engrave wood; leather; textiles; plastics; and stainless, tool and carbon varieties of steel.

Opt Lasers plans to develop 20-W and 30-W compact laser heads.

Related Content

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

-

The Future of High Feed Milling in Modern Manufacturing

Achieve higher metal removal rates and enhanced predictability with ISCAR’s advanced high-feed milling tools — optimized for today’s competitive global market.