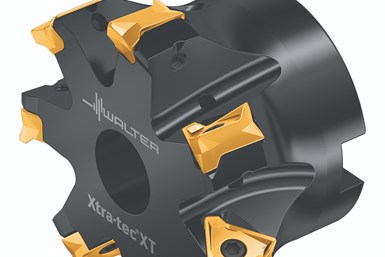

Walter M5137 Xtra-tec XT Cutter Reduces Finishing Operations

Walter’s M5137 Xtra-tec XT shoulder milling cutter features 90-degree approach angles, which it says reduces the need for additional finishing operations.

Share

The M5137 Xtra-tec XT shoulder milling cutter from Walter has six indexes per insert, approach angles of exactly 90 degrees, positive geometry and two pitches for different applications. The company says this cutter’s exact 90-degree lead angle reduces the likelihood of needing additional finishing operations. 鈥婭ts fully sintered, triangular, double-sided indexable inserts improve process reliability and cost efficiency, while the insert design features easy cutting geometry.

A Tiger-tec coating and six cutting edges per indexable insert further reduce the Walter M5137 Xtra-tec XT’s process costs, while also simplifying tool selection and lowering cutting material and unit costs.

Walter says the milling cutter is universally compatible with steel, stainless steels, cast iron and other difficult-to-machine materials. The company recommends it for face, shoulder, ramping, pocket and circular interpolation milling operations in the energy and mold and die industries. The M5137 has a diameter of 2.0-4.0” (50-100 mm), a maximum depth of cut of 0.315” (8 mm) and a shell mill mount interface.

Related Content

-

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

-

The Impact of Cutting Teeth Spacing on Machining Stability

Many cutter designs are available, and variable teeth spacing (or variable pitch) cutters can be used to influence milling stability. Let’s discuss why teeth spacing affects stability.

-

Measuring Torque, Thrust Force for Smart Drilling Operations

To monitor drilling operations for smart manufacturing solutions, torque and thrust force can be measured.