Brent Donaldson Editor-in-Chief

Made in the USA - Season 1 Episode 4: Making the Case for Manufacturing

The majority of Americans want to "bring manufacturing back" to the U.S. The problem? Many of these same people do not want their children to work in manufacturing because of outdated beliefs about what a machine shop looks like.

ListenMade in the USA - Season 1 Episode 3: The Supply Chain Knot

Through interviews with manufacturing leaders and economists, Episode 3 of “Made in the USA” explores the benefits and challenges of keeping manufacturing production within the United States — especially after major events such as 9-11 or the onset of a global pandemic.

ListenMade in the USA - Season 1 Episode 2: The Automation Puzzle

There is a fundamental question we need to answer when we talk about automation: To what extent is automation an answer to the skilled workforce shortage, and to what extent is automation vs. Skilled labor the wrong comparison to make in the first place?

ListenWhen Handing Down the Family Machine Shop is as Complex as a Swiss-Turned Part

The transition into Swiss-type machining at Deking Screw Products required more than just a shift in production operations. It required a new mindset and a new way of running the family-owned business. Hardest of all, it required that one generation let go, and allow a new one to step in.

Read MoreMade in the USA- Season 1 Episode 1: How We Got Here

Episode 1 of Made in the USA Podcast examines manufacturing issues related to trade policy, global supply chains, education, automation and our ability to produce skilled workers.

ListenStarting with the End in Mind: An Exit Strategy for Machine Shops

John Shegda and Eric Wilhelm each had different ideas about how they wanted to phase into retirement. The exit strategies for the three successful manufacturing businesses the two men operated included a mix of seeking equity groups, selling the business, or transitioning into an employee stock ownership plan. All it took was a friendly suggestion from a mutual friend to set them on a different path.

Read MoreHere Is Why Knust Godwin Decided to 3D Print Mission Critical Parts

Knust Godwin introduced metal 3D printing into its precision-machining environment nearly eight years ago. Now the company is using the capability to break through into new applications and give 3D printed mission-critical parts a renewed business case.

Read MoreWhen Organic Growth in Your Machine Shop Isn’t Enough

Princeton Tool wanted to expand its portfolio, increase its West Coast presence, and become a stronger overall supplier. To accomplish all three goals at once, acquiring another machine shop became its best option.

Read MoreInside Oak Ridge’s 3D-Printed Machine Tool Moonshot

The widespread outsourcing of large machine castings led a collaborative team at Oak Ridge National Laboratory to tackle the machine tool supply chain. The first step? 3D print the largest cast component.

Read MoreGrowing Closer: Machine Shops and 3D Printing for Production

Machining a large 3D-printed part for aerospace composite tooling is fundamentally different than manufacturing the part traditionally. Baker Industries knows this first-hand.

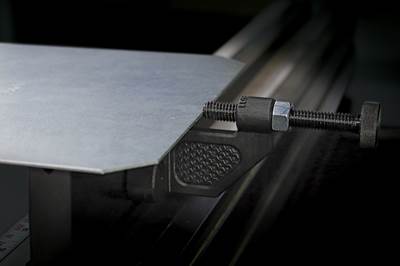

Read MoreA Methodical Strategy to Bring Additive Manufacturing into Sheet Metal Fabrication

When Wilson Tool International launched its additive manufacturing division in 2018, it had already proven 3D printing’s value through dozens of printed parts for its own line of equipment. Demonstrating that value to customers required a new, highly focused approach.

Read MoreHow Machine Tool Dynamics Could Become a U.S. Supply Chain Strategy

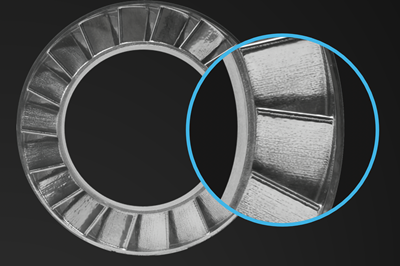

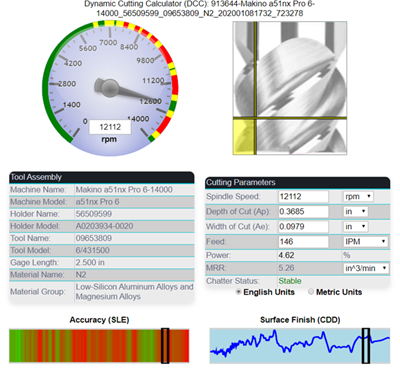

A collaborative agreement being overseen by the U.S. Department of Energy involves a deceptively simple test — a test that could radically increase throughput of the United States’ existing base of CNC machine tools.

Read More