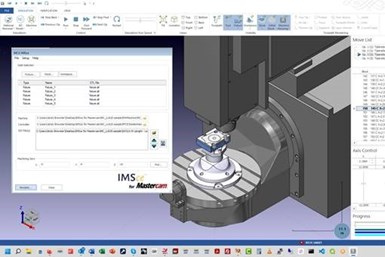

IMS Software, ModuleWorks, Mastercam Collaborate on G-Code Simulation

IMS Software, ModuleWorks and Mastercam’s IMSce combines IMS G-code emulation with the ModuleWorks simulation and post processing technology to provide a G-code parsing solution that connects directly to Mastercam.

Share

IMS Software, ModuleWorks and Mastercam have collaborated on the development of IMSce for Mastercam. The software solution extends the Mastercam machine simulation with G-code parsing and verification for diverse machine tools and controllers.

IMSce for Mastercam combines IMS G-code emulation with the ModuleWorks simulation and post processing technology to provide a G-code parsing solution that connects directly to Mastercam. The solution enables Mastercam users to simulate and verify G-code including controller variables, subprograms, expressions and canned cycles for a wide range of machine tools before the workpiece is mounted on the machine.

Julia Meyer-Hendricks, head of business development – digital manufacturing at ModuleWorks, says, “There is big demand for G-code simulation and it’s great to see how the technologies of different companies are being combined to create value-adding solutions for the industry.”

Dan Wrenn, president and co-founder at IMS Software, adds, “Integrated G-code simulation and verification is a major step forward in complex multi-axis machining, improving code quality and dramatically reducing overall programming time versus traditional standalone solutions.”

Stas Mylek, partnership program manager at Mastercam, says, “We are excited to work together with these industry leaders to offer G-code simulation running inside Mastercam for a wide range of machine tools and controls. As a result, Mastercam users can leverage digital twin technology to simulate and validate their CAM programs, particularly for multiaxis applications, prior to running on their CNC machines.”

Related Content

-

Can AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.

-

2 Secondary Coordinate Systems You Should Know

Coordinate systems tell a CNC machine where to position the cutting tool during the program’s execution for any purpose that requires the cutting tool to move.

-

ERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.