-

SPONSORED

-

SPONSORED

Die/Mold

Fully Committed to Zero Stock Machining

Milling critical mold surfaces to final size (or even a “tenth” undersize) literally leaves no margin for error. This takes absolute confidence in every aspect of the machining process, as well as absolute confidence that the results are worthwhile.

Read MoreAuto EDM Wire Changers Compete at the High End

Automatic EDM wire-change capability can improve efficiency and reduce costs for high-end tool and die work, especially parts with small internal radii.

Read MoreA Big-Picture View of Micromachining

Matrix Tooling makes injection molds for components that have features you cannot see.

Read MoreHigh-Feed Cutters Keep Mold Shops Competitive

Ingersoll cutting tools designed specifically for high-feed machining helped these three mold-makers improve productivity on deep cavities and hostile combinations of layered material.

Read MoreVideo: Micro Inspection at Matrix Tooling

Various inspection and measurement resources help a moldmaker produce tooling for tiny molded parts.

WatchRedefining Plastics Manufacturing

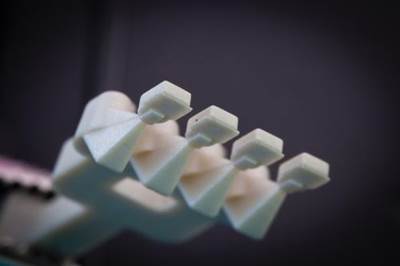

When this company was solely an injection molder, job quantities had to be large. Now, with additive manufacturing, any quantity is right. The company's role and its range of customers have both expanded.

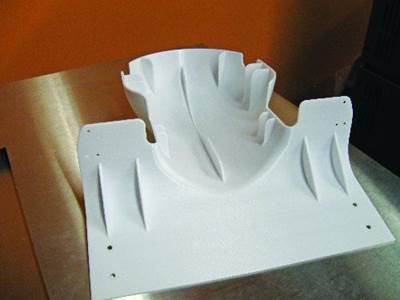

Read MoreConformal Cooling: A Tool in the Toolbox to Build a Better Mold

Moldmakers are just starting to scratch the surface of what can be done with conformal cooling, which involves an additive approach.

Read MoreHow Micromachining Patience Speeds Prototype Production

A molder of tiny, silicone components for the medical industry explains how a patient, conservative approach to micromachining enables it to deliver prototypes faster.

Read MoreCell Controller Boosts Production Flexibility

By serving as the “brains” of a cell consisting of two machining centers and a work delivery system, cell control software from Erowa helps this manufacturer run lights-out 24/7 and achieve 90-percent spindle utilization.

Read MoreSoftware Streamlines Model-to-Mold Production

At Marland Mold, CimatronE CAM software’s modeling tools, postprocessors and other features streamline manufacturing operations from initial design to finished part.

Read More